Today is the best time to implement any technology that leverages your data to provide value. Every day that passes is another missed opportunity to improve business KPIs, deliver for your customers, or improve your company’s intellectual property.

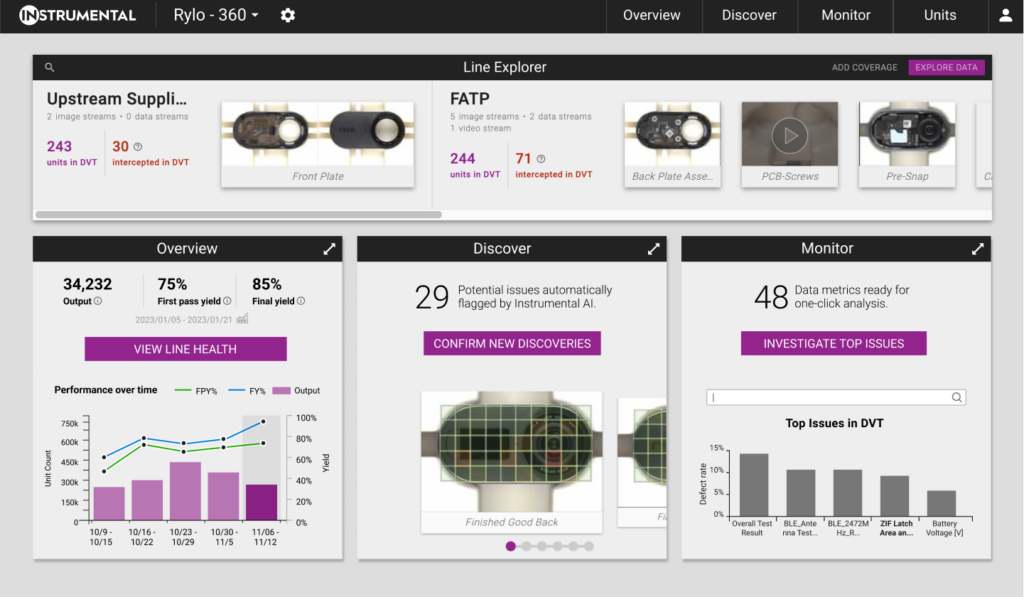

Instrumental’s technology is designed to be low-lift to integrate at any point in the product lifecycle. Aerospace and defense customers implement Instrumental to:

- Scale manufacturing while keeping costs and quality under control

- Improve margin, throughput, and yield

- Stabilize an out-of-control program